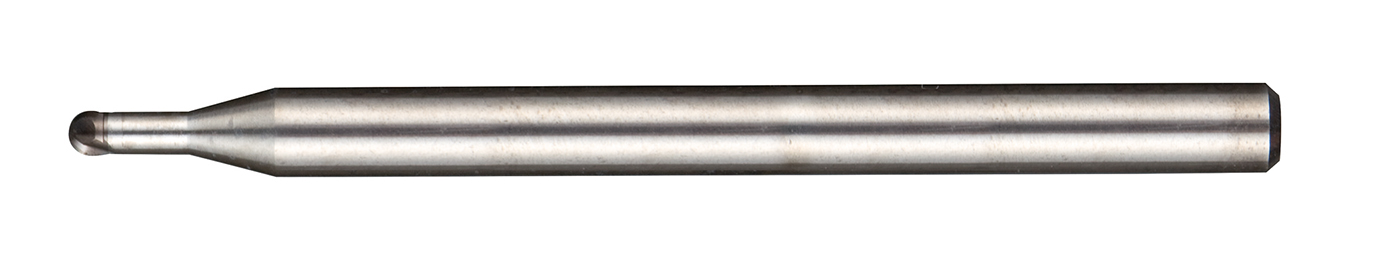

Plunge Cut With Ball End Mill

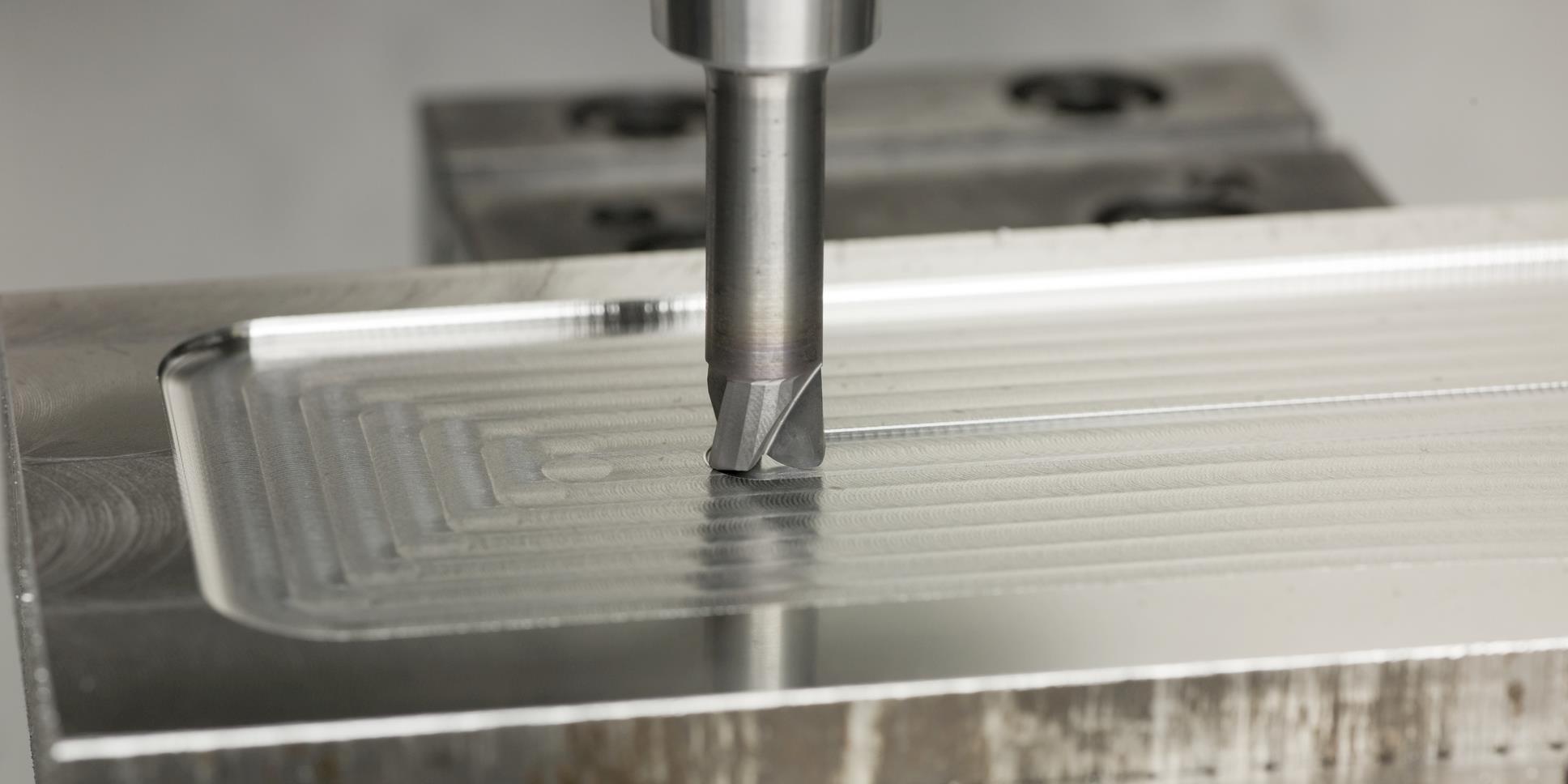

So what type of end mills do you require for general milling applications.

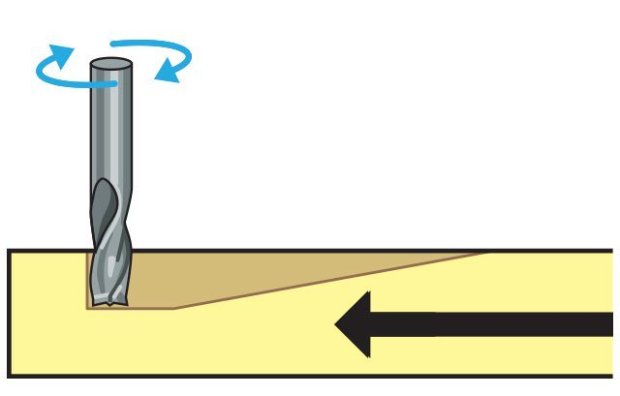

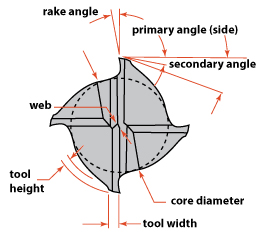

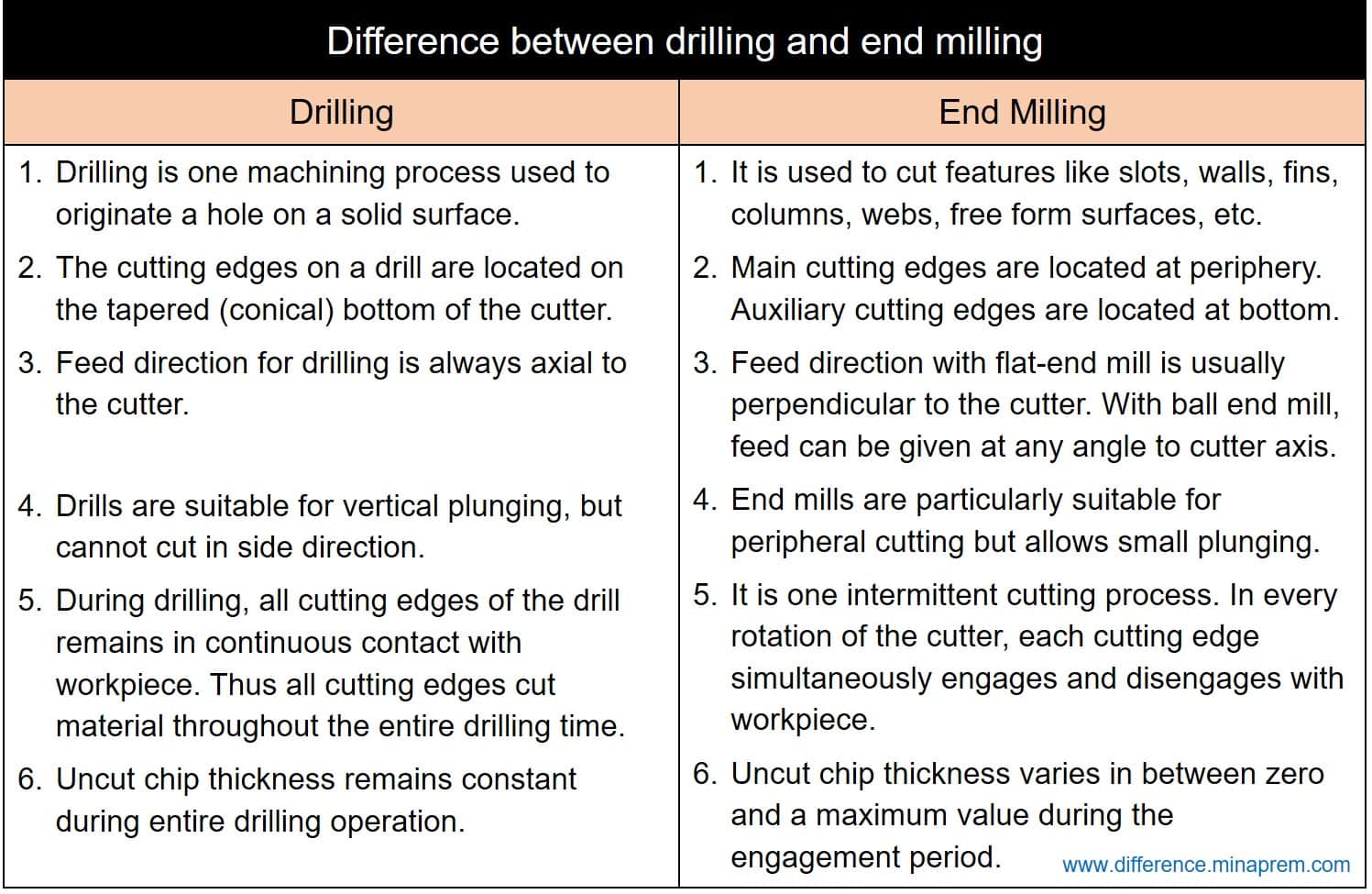

Plunge cut with ball end mill. They use the end of the tool to cut instead of the periphery which beneficially changes the cutting forces from a predominantly radial to axial direction. It can be compared to a boring operation with interrupted cuts. How to apply plunge milling operations cutting process. Keep in mind that end mills are meant to cut from the side whereas drills are meant to cut vertically.

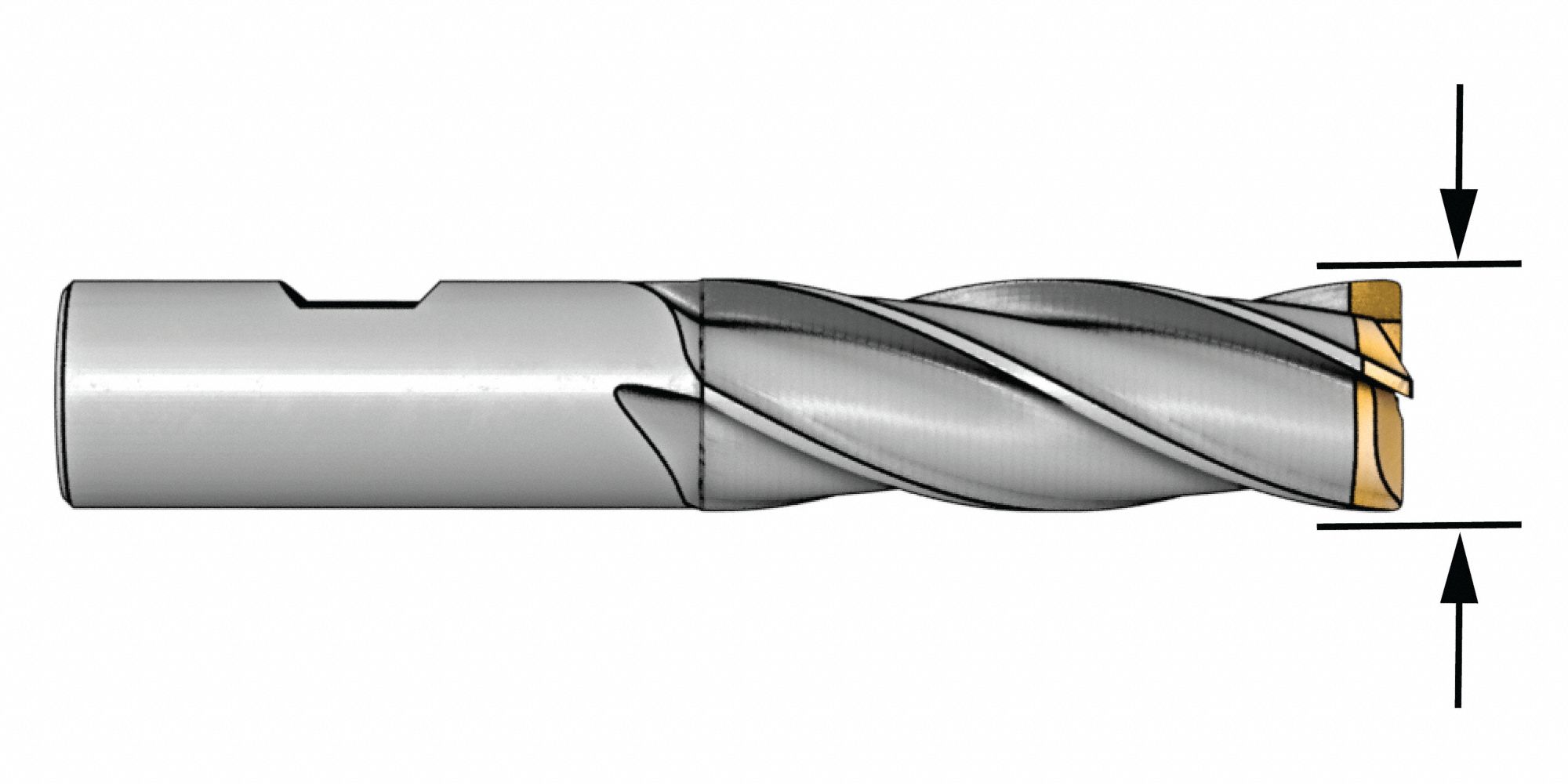

Additionally most mills are center cutting meaning they are able to cut both axially and laterally. 1 1 2 cut diam 0 118 max depth of cut 1 1 4 shank diam indexable plunge end mill straight shank uses htp lnht 1006 insert style htp ln10 toolholder style through coolant. Plunge rate this is the speed at which the bit enters the wood. For most woods i usually set the plunge rate to 10 mmsec or less.

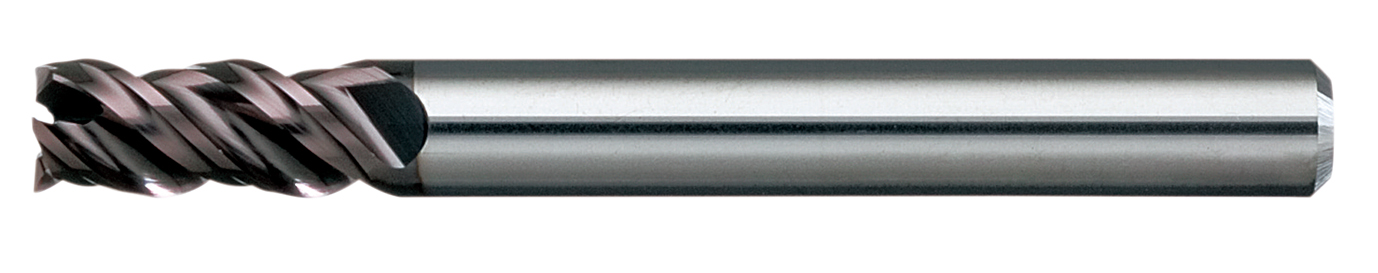

Starter pack end mills. Square end mills are used for general milling applications including slotting profiling and plunge cutting. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. This is due to cutting flutes that extend to and protrude from the end face and enable plunge cutting.

For hardwoods plywood and aluminium. Compression end mills combine the best of both worlds and produce a smooth surface on both ends of the workpiece when cutting. Plunge milling operations vary considerably from traditional milling. You can not plunge an end mill into material like you would a drill bit.