Purlin Spacing For Metal Roofing Nz

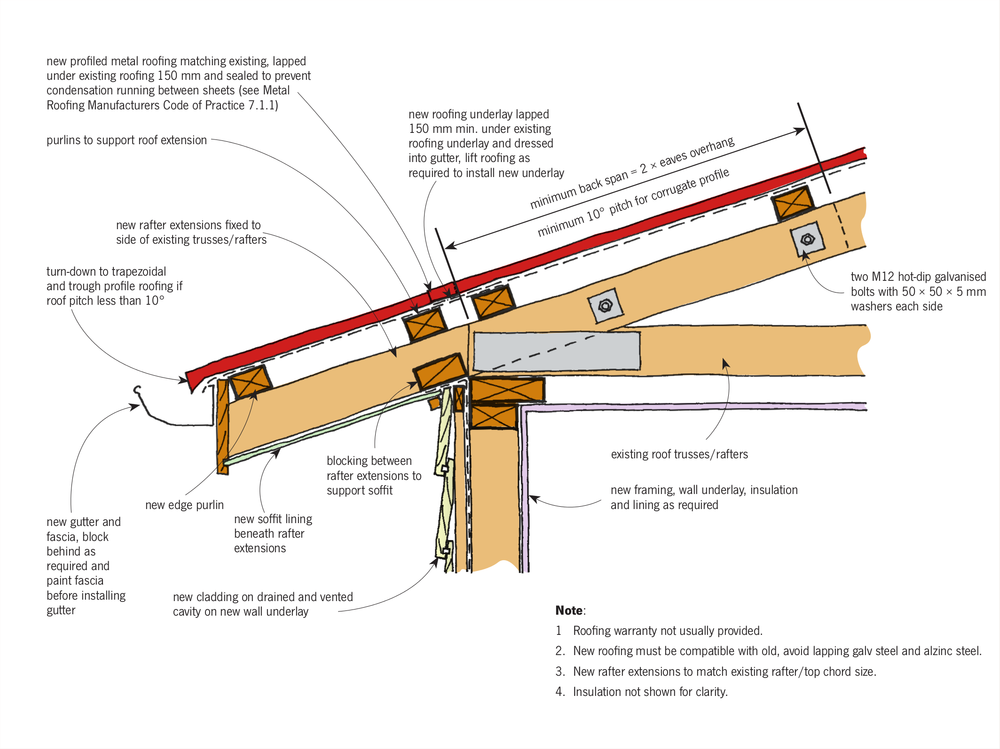

Where the end purlin spacing is less than 800mm an adjustable end brace with a bolted end cleat is available as twisting of the end cleat is not practical.

Purlin spacing for metal roofing nz. If a design quotes wind speed in m s ask for a roof plan showing design loads and purlin spacing apply serviceability loads for pierce fastened products ultimate loads for clip fastened profiles. Mss purlins and girts are available in a variety of sizes and gauges cut to length and prepunched to suit a variety of applications. When the radius of curvature is close to the minimum the purlin spacing should be reduced to the end span distance for each gauge and profile. Fastener patterns on nzs 3604 buildings should be consistent throughout the roof excluding top and bottom rows.

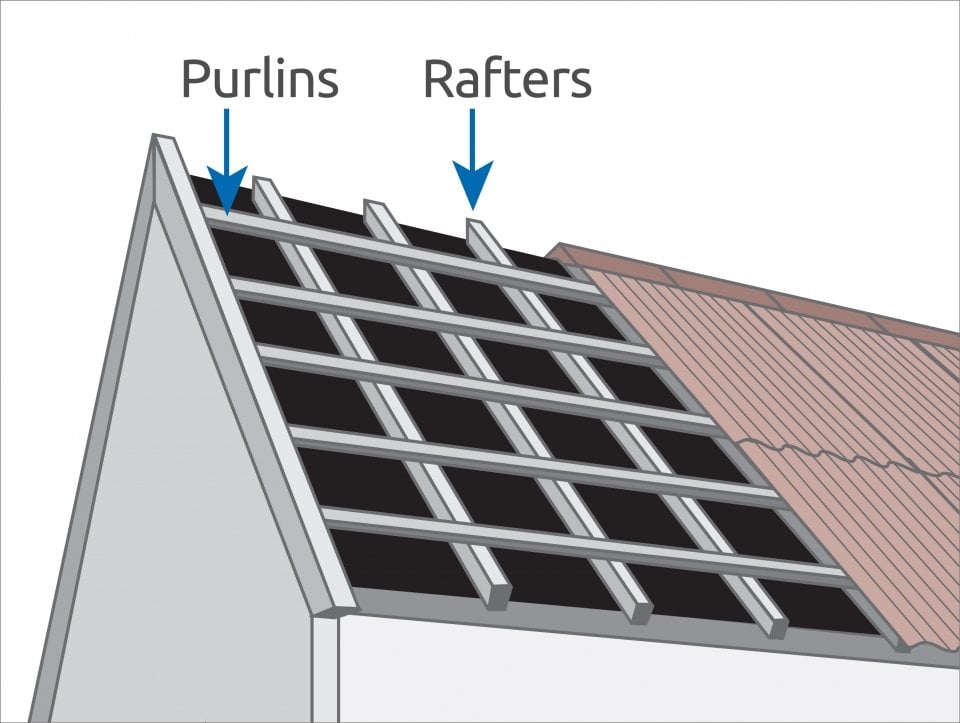

Metalcraft roofing s structural division manufactures metalcraft super span shortened to mss purlins and girts for the new zealand construction market and the pre engineered garages and sheds market segment. When the purlin spacing is close to the maximum allowable for the profile and ease of curvature the roof cladding is more likely to be damaged by foot traffic and distortion between the purlins. The adjustable cleat can be rotated up to 15 degrees from normal to accommodate the change in angle from vertical portal to the roof slope of the rafter. Purlins are non pressure treated 1 x 4 x 12 lumber that is installed on to the roof in a specific layout pattern and screw pattern.

April 2012 nz metal roof and wall cladding code of practice table of contents v 2 2 page 3 table of contents 1 1 0 table of contents 2 0p erformance 3 0 construction load 4 0 d esign 5 0f lashings 6 0p enetrations 7 0i nstallation 8 0 roof drainage 9 0 plastic roof lighting 10 0 pressed metal tiles. Roof bracing hipped roof construction does not require additional bracing but gabled roofs require both roof plane and roof space bracing. Do all roofing projects require purlins. Purlins typically 75 x 50 mm and fixed across the rafters were spaced at 760 900 mm centres depending on the roof cladding.

The purpose of the purlins is to provide a solid foundation for the metal roofing panels and trim to be screwed to. The purlin spacings should be limited to the lower of the trafficable limitations and design wind load with the capacity of the structure. For a fuller explanation of this refer to the nz metal roof and wall cladding code of practice. For heavier material such as gage steel the metal roof purlins spacing length could go up to 4 feet.

This result should be referenced to the wind load span design graphs. Purlins up to 1200mm spacing must be fixed with a 1 10g 80mm long purlin screw minimum or a pryda purlin strap bs 70. It often depends on the wideness thickness and the types of roofing materials the climate it has to withstand and many other factors.