Purlin Spacing For Pvc Corrugated Roofing

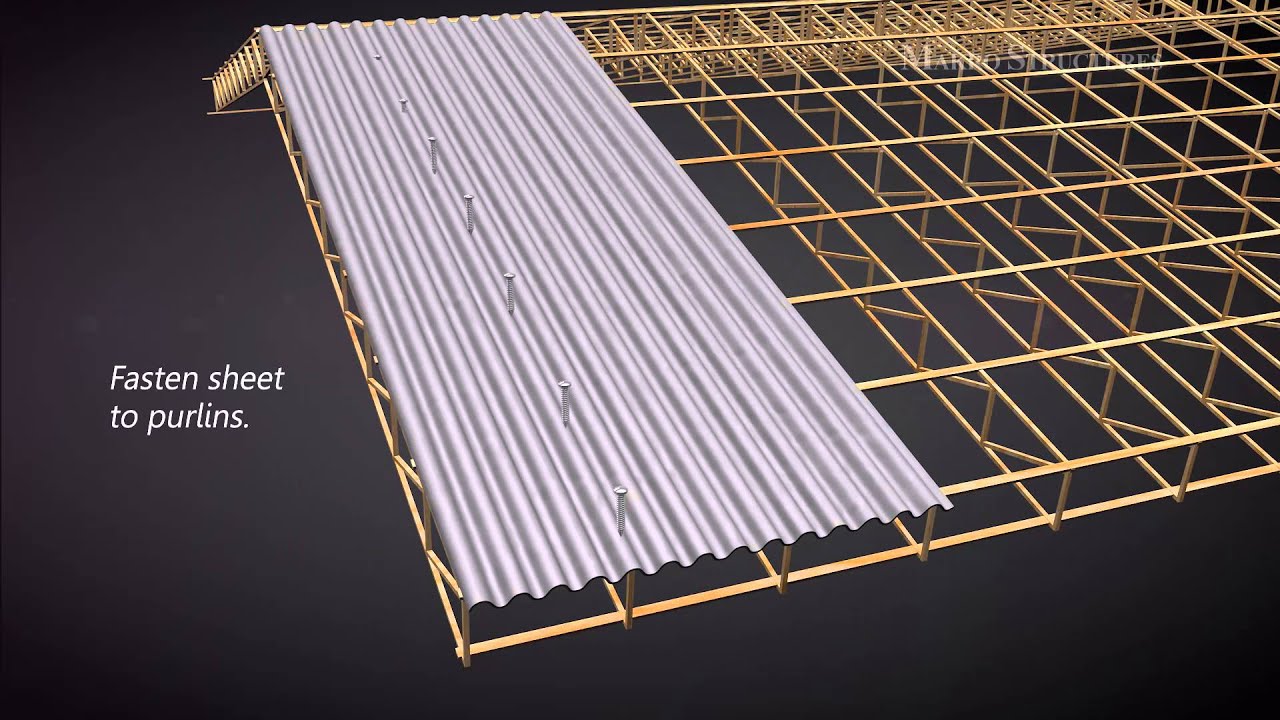

Installing translucent plastic corrugated roof panels.

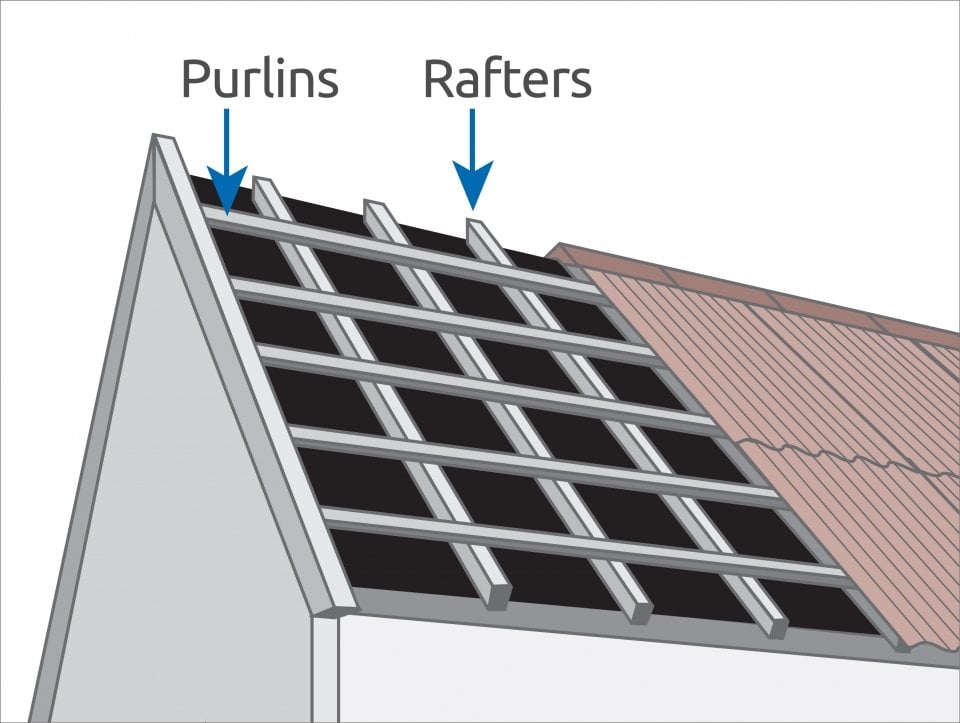

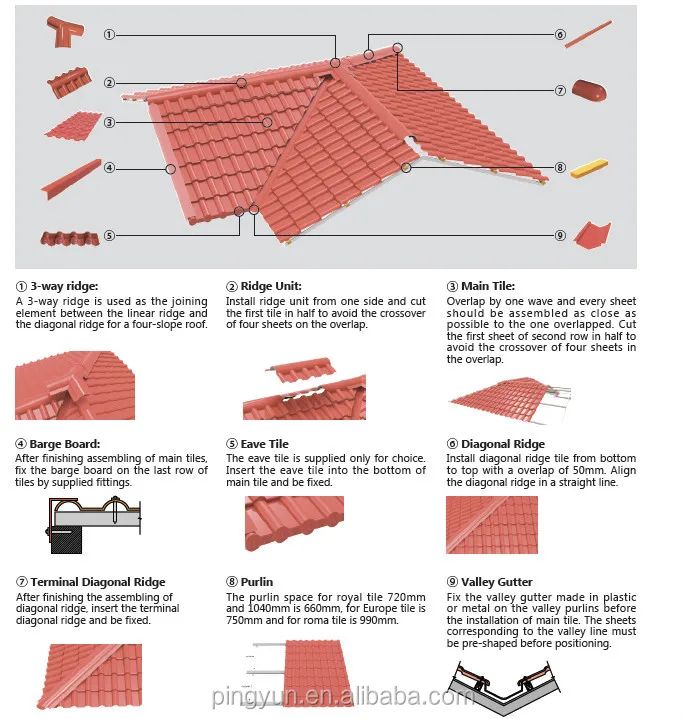

Purlin spacing for pvc corrugated roofing. You can use both types of corrugated roofing together creating panels that will allow light to come through as with a clear or white fiberglass corrugated panel known as a skylight. The overlaps ends and sides depends upon the sloop of the roof see below. In the valleys due to the angle typically produced at the valley and the use of transition flashing it is essential that the purlins are doubled in the valleys that is two purlins side by side on each side of the angle of the valley. Corrugated sheet roofing material is widely available and easy to use.

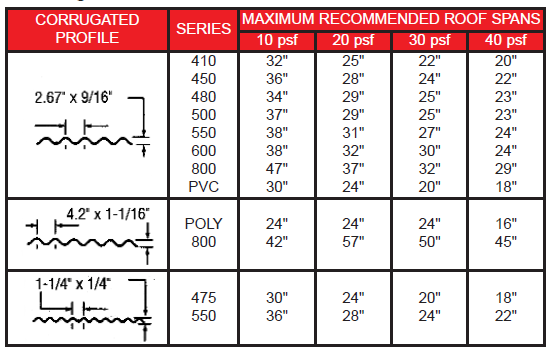

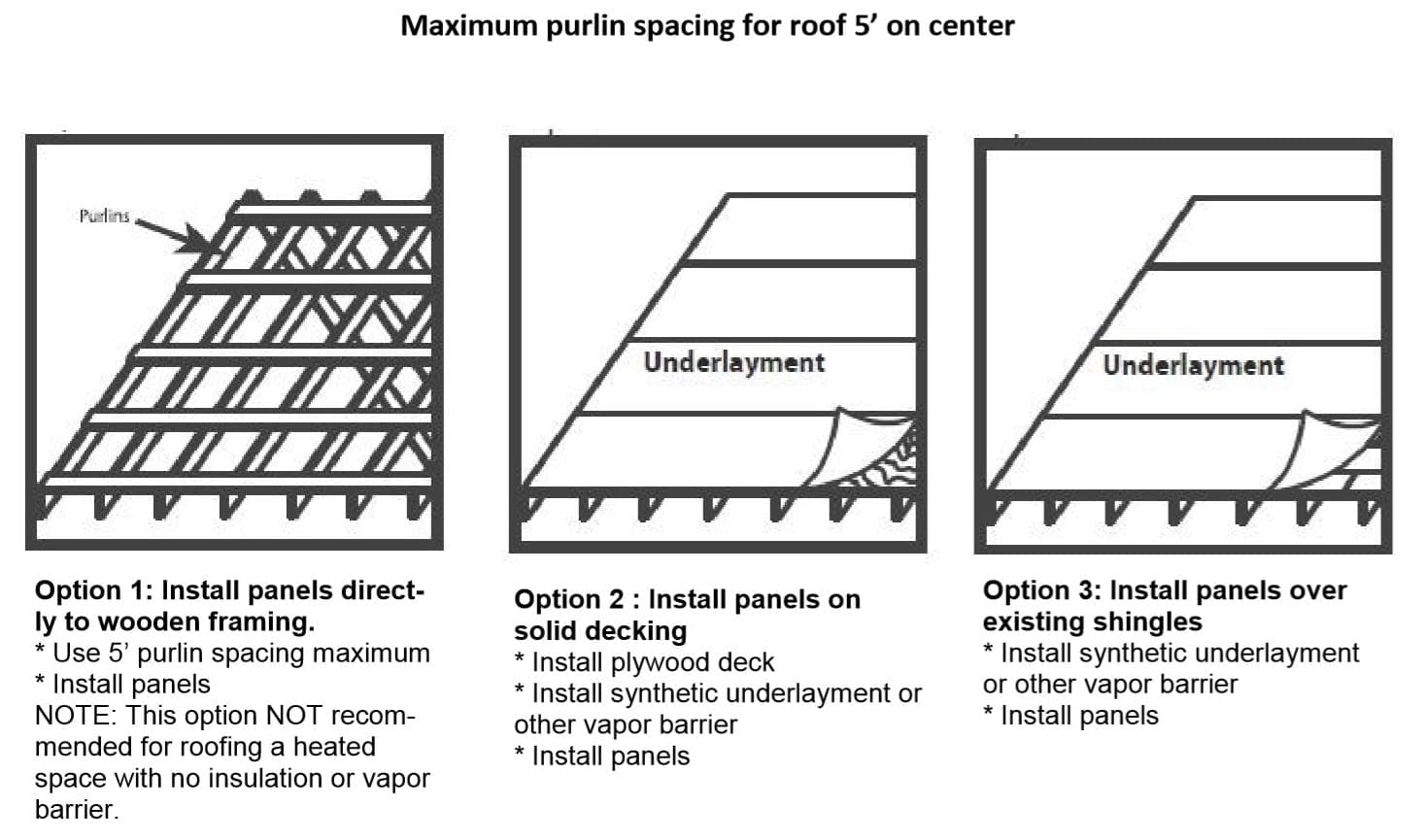

Installations with purlin spacing greater than 24 may result in increased do not leave partly installed panels unattended until all the required fasteners have been placed and properly tightened. Suntuf is supported on the structure via purlins these are the bearers that run left to right along the width of the roof the maximum purlin spacing for the corrugated profile is 800mm centres on the first and last purlins and 1 meter centres for the intermediate purlins. For the greca profile 900mm first and last and 1200mm for the intermediates. While panels may not fail under heavy snow loads strain at fastening points can cause slight cracking.

Step 3 purlin spacing. Purlin batten spacing s please refer to table for purlin batten spacing s. Overhang at eaves should not exceed 100mm and be less in high wind areas. Spacings should be reduced to 750mm maximum end spans in areas exposed to high winds.

Endlap at battens or purlins should not exceed 200mm to reduce. Plastic is much lighter and easier to work with making it popular with homeowners looking to save money that could be spent hiring professional installation teams. When framing the roof the spacing for roof trusses should not exceed 24 inches 61 cm and purlins should not exceed 36 inches 91 cm apart. Doubling up in the valleys refer to the installation manual for the proper on center spacing and be sure that the purlin is attached to the roofing truss.

For the lighter material such as lightweight aluminum the common spacing length is 4 inches of clear gap. Non accessible roof and intermediate 1 600 2 400 1 500 2 100 wall cladding type 3 end 1 100 1 600 1 000 1 400 maximum recommended purlin intermediate 0 900 1 500 0 800 1 200 spacing for standard roof end 0 600 1 000 0 550 0 800 see notes below. In heavy snow areas 500 series or greater panels are recommended and closer spacing of purlins should be considered. The typical spacing standards for residential and commercial buildings are about 1 to 2 foot.

Purlin spacing should suit the end laps required for the size of sheet to be used. In order to install your plastic roof correctly and prevent leaks you.